Moving Floor Fuel Handling

System (Push Floor Discharger)

Biomass

boilers

For

warm water

- BIO

Automated, pellet, wood chips,

- Farmer

Automated, pellet,wood chips,

wood logs, multifuel

- Automat

Self-loading, automated, pellet, wood chips, multifuel

- Low pressure steam (0,5bar) automated boilers for biomass, pellet, wood chips, multifuel

- Automated brown coal boilers

For warm water or low pressure steam

- Feedlan

control

Solid-fuel handling system

- Moving

floor

Automated solid-fuel store

- Fuel

stores

For solid-fuel

- Augers

- Loader spoon

- Ash

removing

| Moving Floor Fuel Handling System | |

Video |

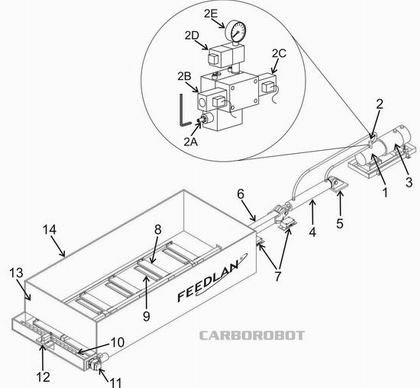

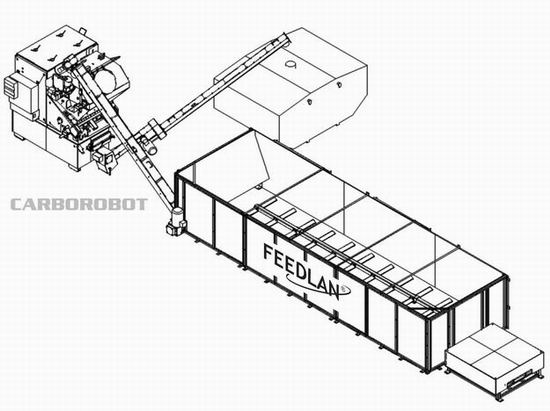

The moving floor (or Scraper Floor) is an important part of the boiler’s fuel handling system. It is the largest storage capacity storage. Its importance is mainly wood chips, storage. But practically all kinds of granular material offers superior handling (coal, pellet, grain, wood chips).The moving floor receives, stores and delivers fuel through the use of hydraulic operated wedge-shaped grid at the bottom of the fuel storage bin. These ladders carry the fuel to the external augers to deliver the fuel into the boiler’s feeder system. The storage controlled via PLC or microcomputer, can be adapted to the charger system. |

|

|

Large moving floor storages

Beszterec 60m3

Mezőszemere 90m3

Nyíradony 90m3

Hajdúböszörmény 30m3

| Direct feeding |

|

|

Copyright © 2023 CARBOROBOT

Contact informations tel/fax:+36-13852-862

info@carborobot.com